4 Wheel Drive & SUV Magazine takes an inside look at King Shocks

High-End Shock Performance - Shock Value

Small Parts, Big Difference

From the February, 2010 issue of 4Wheel Drive & Sport Utility

By Kevin Blumer

Photography by Kevin Blumer, King Shocks

Shocks come in a whole spectrum of prices. We decided to concentrate on high-end shocks this time because they're the most tunable, last the longest, and can make the biggest difference in comfort, safety, and most importantly, fun. Yes, basic shocks cost less and can usually be bolted to the same set of mounts, but you really do get what you pay for.

To hammer the point home, we consulted industry leader whose products have hundreds of thousands of off-road miles to their names. Who is the leader? King Shocks.

Turned inside-out to expose their guts, we found premium materials, precision machining, and superior design. Assembled, tuned, and bolted to your rig, they're nothing short of a revelation. They're small parts that make a big difference. We think you'll find that high-end shocks are a big-time value.

These are the components that make up a King coilover shock. It's pretty obvious there's a lot happening in between the blue-anodized end cap and rod end. While most of the shock is filled with oil, the reservoir is partially filled with oil and partially with nitrogen. There's a dividing piston floating in the reservoir, separating the oil and nitrogen. As oil heats up, it expands against the dividing piston and the nitrogen which in turn compress into a smaller area. As oil cools down, it contracts and the nitrogen then expands to take up the "slack." In short, the reservoir's purpose is to keep shock action smooth and consistent.

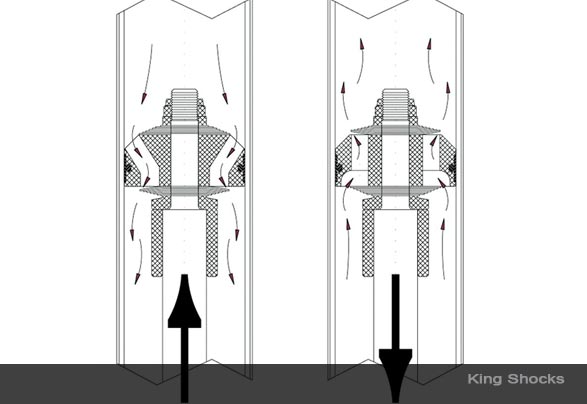

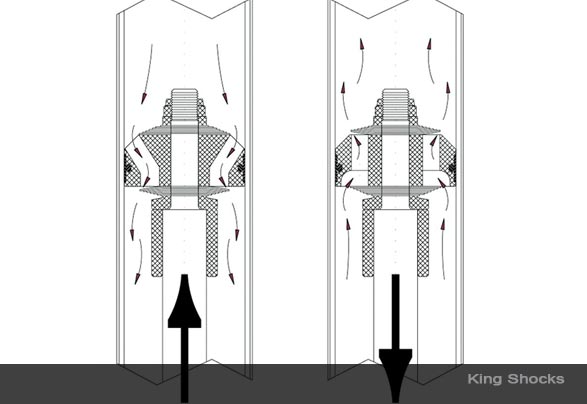

Inside a shock you'll find oil, an actuating rod, a piston, and two sets of flexible shims that determine how fast the piston can pass through the oil. On the left, the piston is traveling upwards in compression. Holes (ports) in the piston head allow the piston to move through the oil. When the oil encounters the flexible shims on the underside of the piston, those shims flex the shims away from the face of the piston. If the shims flex more, the piston can travel through the oil more quickly. If the shims flex less, the piston travels through the oil more slowly. On the right, the piston is traveling downwards during the rebound stroke. This time, the compression shims are forced closed against the face of the piston and the oil travels though a set of rebound holes (ports) in the piston head. A set of rebound shims on the top of the piston head now flexes open. The degree of flex determines how fast or slow the rebound stroke will be.

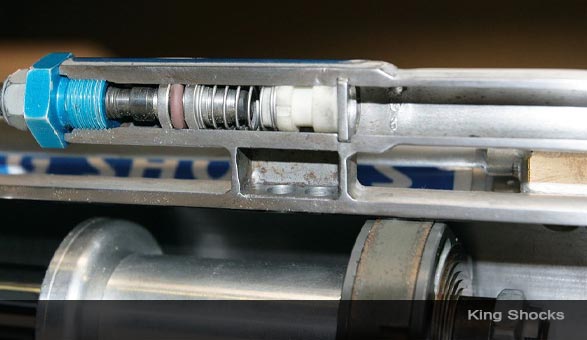

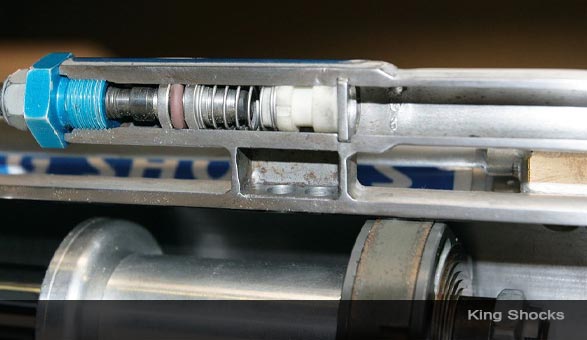

Shock valving shims come in different diameters, and varying thicknesses. The widest shims are usually assembled directly against the piston, and smaller shims get stacked progressively on top. Shock valving shims also come in different thicknesses. The thicker the shim, the more energy it takes to deflect it. Most changes in shock valving are done by changing the number, arrangement, and thickness of the shims.

Here's a view of the business end of a monster-sized 4.0 King Kong shock. On the top of the piston, you can see the intake ports for the compression stroke around the perimeter. The rebound shim stack is bolted to the top of the piston, and the progressive diameters are easy to see. Brett King informed us that "Shocks are like engines. They need to run at around 200 degrees to work properly. At that temperature, you can't touch the shock or it will burn you, but that doesn't mean it's overheated. At the same time, 300-degree shock oil is too hot. At that temperature the oil will break down."

Here are the most common coilover configurations. Left to right: remote reservoir, piggyback reservoir, and non-reservoir/emulsion. With an emulsion shock, the oil and the nitrogen occupy the same space and there is no dividing piston. The piggyback and the remote reservoir configurations offer the best performance, but tight mounting spaces sometimes mean no room for a reservoir.

King offers its air shocks in 2- and 2.5-inch diameters. Air bypass shocks, not shown, are also on the King menu. Air shocks are compact, easy to adjust, and offer a streamlined installation with a single set of upper and lower shock tabs. Even though today's air shocks are better than older versions, King recommends that its air shocks be used on lightweight vehicles only, and only for off-road-specific applications. This means air shocks are a perfect choice for a lightweight rock buggy, but not for a street-driven

King Shocks has developed a line of bolt-in shocks for TJ and JK Wranglers. These Kings can be ordered to work with stock or with brand-and-height-specific lifted suspension. "You can call us up and say you need a set of our shocks for a TJ with a 4-inch Teraflex suspension, and we'll have the right shock," Lance King told us. Brett King added "We've taken the time to make sure that the shocks are the correct length, both extended and collapsed. That means that the coil won't fall out at full extension and that the bump stop still functions properly at full compression." In addition to tuning their Jeep shocks' lengths, King has developed custom valving to smooth and control the ride. The shocks bolt in without any custom fabrication.

King's optional compression adjuster, shown on a TJ shock here, can be added to any remote reservoir or piggyback reservoir shock. There are 20 positions, offering a wide range of compression damping that's tunable with the twist of a knob.

King eliminates the stock cross pin on Wrangler applications, replacing it with a custom King bracket that's much stronger.

King bump stops come into play when the suspension hits the last few inches of compression travel. They are available in stroke lengths from two to four inches to accommodate a variety of vehicles and suspension configurations. The mounting cans are honed inside to ensure a precise fit.

King has a growing line of OEM performance kits. These kits bolt up to stock vehicles with no other modifications required. Brackets and hardware are included. Like the TJ and JK Wrangler shocks, custom valving was developed for each application. This photo shows King's OEM kit for the FJ Cruiser.

These are the components that make up a King coilover shock. It's pretty obvious there's a lot happening in between the blue-anodized end cap and rod end. While most of the shock is filled with oil, the reservoir is partially filled with oil and partially with nitrogen. There's a dividing piston floating in the reservoir, separating the oil and nitrogen. As oil heats up, it expands against the dividing piston and the nitrogen which in turn compress into a smaller area. As oil cools down, it contracts and the nitrogen then expands to take up the "slack." In short, the reservoir's purpose is to keep shock action smooth and consistent.

These are the components that make up a King coilover shock. It's pretty obvious there's a lot happening in between the blue-anodized end cap and rod end. While most of the shock is filled with oil, the reservoir is partially filled with oil and partially with nitrogen. There's a dividing piston floating in the reservoir, separating the oil and nitrogen. As oil heats up, it expands against the dividing piston and the nitrogen which in turn compress into a smaller area. As oil cools down, it contracts and the nitrogen then expands to take up the "slack." In short, the reservoir's purpose is to keep shock action smooth and consistent.

Inside a shock you'll find oil, an actuating rod, a piston, and two sets of flexible shims that determine how fast the piston can pass through the oil. On the left, the piston is traveling upwards in compression. Holes (ports) in the piston head allow the piston to move through the oil. When the oil encounters the flexible shims on the underside of the piston, those shims flex the shims away from the face of the piston. If the shims flex more, the piston can travel through the oil more quickly. If the shims flex less, the piston travels through the oil more slowly. On the right, the piston is traveling downwards during the rebound stroke. This time, the compression shims are forced closed against the face of the piston and the oil travels though a set of rebound holes (ports) in the piston head. A set of rebound shims on the top of the piston head now flexes open. The degree of flex determines how fast or slow the rebound stroke will be.

Inside a shock you'll find oil, an actuating rod, a piston, and two sets of flexible shims that determine how fast the piston can pass through the oil. On the left, the piston is traveling upwards in compression. Holes (ports) in the piston head allow the piston to move through the oil. When the oil encounters the flexible shims on the underside of the piston, those shims flex the shims away from the face of the piston. If the shims flex more, the piston can travel through the oil more quickly. If the shims flex less, the piston travels through the oil more slowly. On the right, the piston is traveling downwards during the rebound stroke. This time, the compression shims are forced closed against the face of the piston and the oil travels though a set of rebound holes (ports) in the piston head. A set of rebound shims on the top of the piston head now flexes open. The degree of flex determines how fast or slow the rebound stroke will be.

Shock valving shims come in different diameters, and varying thicknesses. The widest shims are usually assembled directly against the piston, and smaller shims get stacked progressively on top. Shock valving shims also come in different thicknesses. The thicker the shim, the more energy it takes to deflect it. Most changes in shock valving are done by changing the number, arrangement, and thickness of the shims.

Shock valving shims come in different diameters, and varying thicknesses. The widest shims are usually assembled directly against the piston, and smaller shims get stacked progressively on top. Shock valving shims also come in different thicknesses. The thicker the shim, the more energy it takes to deflect it. Most changes in shock valving are done by changing the number, arrangement, and thickness of the shims.

Here's a view of the business end of a monster-sized 4.0 King Kong shock. On the top of the piston, you can see the intake ports for the compression stroke around the perimeter. The rebound shim stack is bolted to the top of the piston, and the progressive diameters are easy to see. Brett King informed us that "Shocks are like engines. They need to run at around 200 degrees to work properly. At that temperature, you can't touch the shock or it will burn you, but that doesn't mean it's overheated. At the same time, 300-degree shock oil is too hot. At that temperature the oil will break down."

Here's a view of the business end of a monster-sized 4.0 King Kong shock. On the top of the piston, you can see the intake ports for the compression stroke around the perimeter. The rebound shim stack is bolted to the top of the piston, and the progressive diameters are easy to see. Brett King informed us that "Shocks are like engines. They need to run at around 200 degrees to work properly. At that temperature, you can't touch the shock or it will burn you, but that doesn't mean it's overheated. At the same time, 300-degree shock oil is too hot. At that temperature the oil will break down."

Here are the most common coilover configurations. Left to right: remote reservoir, piggyback reservoir, and non-reservoir/emulsion. With an emulsion shock, the oil and the nitrogen occupy the same space and there is no dividing piston. The piggyback and the remote reservoir configurations offer the best performance, but tight mounting spaces sometimes mean no room for a reservoir.

Here are the most common coilover configurations. Left to right: remote reservoir, piggyback reservoir, and non-reservoir/emulsion. With an emulsion shock, the oil and the nitrogen occupy the same space and there is no dividing piston. The piggyback and the remote reservoir configurations offer the best performance, but tight mounting spaces sometimes mean no room for a reservoir.

King offers its air shocks in 2- and 2.5-inch diameters. Air bypass shocks, not shown, are also on the King menu. Air shocks are compact, easy to adjust, and offer a streamlined installation with a single set of upper and lower shock tabs. Even though today's air shocks are better than older versions, King recommends that its air shocks be used on lightweight vehicles only, and only for off-road-specific applications. This means air shocks are a perfect choice for a lightweight rock buggy, but not for a street-driven

King offers its air shocks in 2- and 2.5-inch diameters. Air bypass shocks, not shown, are also on the King menu. Air shocks are compact, easy to adjust, and offer a streamlined installation with a single set of upper and lower shock tabs. Even though today's air shocks are better than older versions, King recommends that its air shocks be used on lightweight vehicles only, and only for off-road-specific applications. This means air shocks are a perfect choice for a lightweight rock buggy, but not for a street-driven

King Shocks has developed a line of bolt-in shocks for TJ and JK Wranglers. These Kings can be ordered to work with stock or with brand-and-height-specific lifted suspension. "You can call us up and say you need a set of our shocks for a TJ with a 4-inch Teraflex suspension, and we'll have the right shock," Lance King told us. Brett King added "We've taken the time to make sure that the shocks are the correct length, both extended and collapsed. That means that the coil won't fall out at full extension and that the bump stop still functions properly at full compression." In addition to tuning their Jeep shocks' lengths, King has developed custom valving to smooth and control the ride. The shocks bolt in without any custom fabrication.

King Shocks has developed a line of bolt-in shocks for TJ and JK Wranglers. These Kings can be ordered to work with stock or with brand-and-height-specific lifted suspension. "You can call us up and say you need a set of our shocks for a TJ with a 4-inch Teraflex suspension, and we'll have the right shock," Lance King told us. Brett King added "We've taken the time to make sure that the shocks are the correct length, both extended and collapsed. That means that the coil won't fall out at full extension and that the bump stop still functions properly at full compression." In addition to tuning their Jeep shocks' lengths, King has developed custom valving to smooth and control the ride. The shocks bolt in without any custom fabrication.

King's optional compression adjuster, shown on a TJ shock here, can be added to any remote reservoir or piggyback reservoir shock. There are 20 positions, offering a wide range of compression damping that's tunable with the twist of a knob.

King's optional compression adjuster, shown on a TJ shock here, can be added to any remote reservoir or piggyback reservoir shock. There are 20 positions, offering a wide range of compression damping that's tunable with the twist of a knob.

King eliminates the stock cross pin on Wrangler applications, replacing it with a custom King bracket that's much stronger.

King eliminates the stock cross pin on Wrangler applications, replacing it with a custom King bracket that's much stronger.

King bump stops come into play when the suspension hits the last few inches of compression travel. They are available in stroke lengths from two to four inches to accommodate a variety of vehicles and suspension configurations. The mounting cans are honed inside to ensure a precise fit.

King bump stops come into play when the suspension hits the last few inches of compression travel. They are available in stroke lengths from two to four inches to accommodate a variety of vehicles and suspension configurations. The mounting cans are honed inside to ensure a precise fit.

King has a growing line of OEM performance kits. These kits bolt up to stock vehicles with no other modifications required. Brackets and hardware are included. Like the TJ and JK Wrangler shocks, custom valving was developed for each application. This photo shows King's OEM kit for the FJ Cruiser.

King has a growing line of OEM performance kits. These kits bolt up to stock vehicles with no other modifications required. Brackets and hardware are included. Like the TJ and JK Wrangler shocks, custom valving was developed for each application. This photo shows King's OEM kit for the FJ Cruiser.

You must login to post comments.