Cooler By Design

Engineering is the application of science into a design. Every new design begins with an idea. From that idea you develop a concept. The concept is then made into a prototype. The prototype is tested and revised as needed. All along the way engineers make careful calculations and use whatever tools are available to prove their theories and make their prototype work. Lab testing can get you close but there is no substitute for real world conditions. When testing in the real world, you have to deal with countless variables. No two cars are identical and test conditions are ever changing. Very rarely can you get accurate comparison data due to those countless variables.

King Shocks set out to do a direct comparison between a standard remote reservoir and their new finned reservoir that uses convection cooling to lower the shock oil temperature. Heat flows, it naturally moves from high temperature areas to low temperature areas. The more surface area exposed to cooler outside air the faster the temperature will drop. The fins on the reservoir create a huge increase in surface area. The rules of thermodynamics will tell you the finned reservoir will provide additional cooling; but how much, that’s the question.

The idea for the test was simple; two similar cars, one with a standard reservoir and one with the new finned reservoir would compete in the Score, San Felipe 250. The miles of sandy whoops that make up most of the San Felipe race course are known for punishing shocks. The constant, high speed cycling sends shock fluid temperatures through the roof.

King would enlist the help of Wilson Motorsports and their nearly identical Jimco, class one racecars. Randy and Ronny Wilson and their crewchief Mike Stapleton have worked with King Shocks for years helping to test King’s latest ideas. The two cars share the same engines, transmissions, suspensions and shock packages. Everyone involved was hoping to get valid results but nobody expected how equally the cars would perform and how accurate the test data would be. They would each run trouble free all day. They started the race and finished about five minutes apart taking second and third in class one.

According to King Shocks engineer Jeff Larson’s official report:

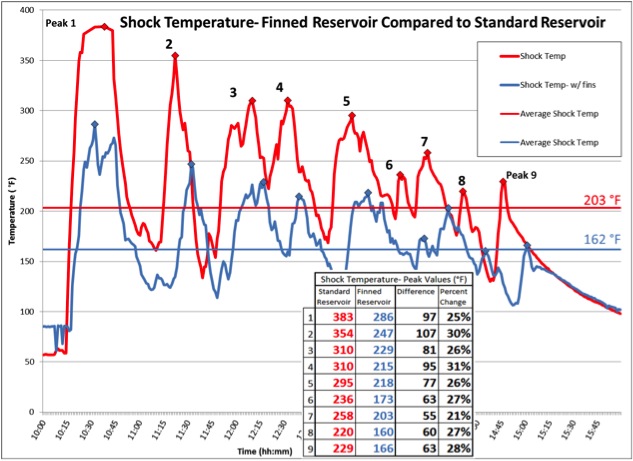

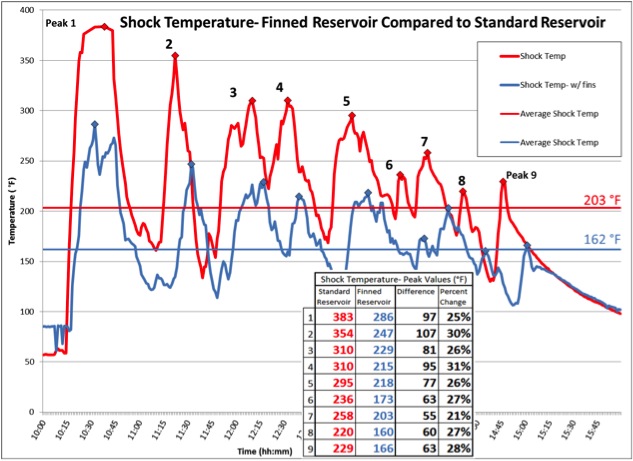

Test data was recorded by the use of two identical temperature data loggers. Each logger had 3 thermocouple channels available and was programmed to record the temperature of all three channels once every minute. The data gathered was graphed vs. time. The profile of each car had similar peaks and valleys. The cars performed similarly all day as the terrain on the race course and the speed of the cars changed creating temperature cycles. Since both cars had the same cycles, it is reasonable to compare peak temperatures between the cars as well as averages. A laboratory test could not have been any better. The fact that the cars both finished the race without problems within similar times makes the value of the collected data priceless.

The temperatures on the shock with the finned reservoir were up to 107 degrees cooler then the same shock with a standard reservoir. That’s a 30% reduction in peak temperature under the most extreme racing conditions. The new finned reservoir from King is durable, has no moving parts and is proven to reduce temperatures. The finned reservoir is currently available for 4.0 and 4.5 diameter shocks with more applications in the works. When you ride on King shocks you’ll know, there really is a difference. Nothing rides like a King.

Photos By: High Rev Photography, Mikes Race Photo.com

Engineering is the application of science into a design. Every new design begins with an idea. From that idea you develop a concept. The concept is then made into a prototype. The prototype is tested and revised as needed. All along the way engineers make careful calculations and use whatever tools are available to prove their theories and make their prototype work. Lab testing can get you close but there is no substitute for real world conditions. When testing in the real world, you have to deal with countless variables. No two cars are identical and test conditions are ever changing. Very rarely can you get accurate comparison data due to those countless variables.

King Shocks set out to do a direct comparison between a standard remote reservoir and their new finned reservoir that uses convection cooling to lower the shock oil temperature. Heat flows, it naturally moves from high temperature areas to low temperature areas. The more surface area exposed to cooler outside air the faster the temperature will drop. The fins on the reservoir create a huge increase in surface area. The rules of thermodynamics will tell you the finned reservoir will provide additional cooling; but how much, that’s the question.

Engineering is the application of science into a design. Every new design begins with an idea. From that idea you develop a concept. The concept is then made into a prototype. The prototype is tested and revised as needed. All along the way engineers make careful calculations and use whatever tools are available to prove their theories and make their prototype work. Lab testing can get you close but there is no substitute for real world conditions. When testing in the real world, you have to deal with countless variables. No two cars are identical and test conditions are ever changing. Very rarely can you get accurate comparison data due to those countless variables.

King Shocks set out to do a direct comparison between a standard remote reservoir and their new finned reservoir that uses convection cooling to lower the shock oil temperature. Heat flows, it naturally moves from high temperature areas to low temperature areas. The more surface area exposed to cooler outside air the faster the temperature will drop. The fins on the reservoir create a huge increase in surface area. The rules of thermodynamics will tell you the finned reservoir will provide additional cooling; but how much, that’s the question.

The idea for the test was simple; two similar cars, one with a standard reservoir and one with the new finned reservoir would compete in the Score, San Felipe 250. The miles of sandy whoops that make up most of the San Felipe race course are known for punishing shocks. The constant, high speed cycling sends shock fluid temperatures through the roof.

King would enlist the help of Wilson Motorsports and their nearly identical Jimco, class one racecars. Randy and Ronny Wilson and their crewchief Mike Stapleton have worked with King Shocks for years helping to test King’s latest ideas. The two cars share the same engines, transmissions, suspensions and shock packages. Everyone involved was hoping to get valid results but nobody expected how equally the cars would perform and how accurate the test data would be. They would each run trouble free all day. They started the race and finished about five minutes apart taking second and third in class one.

The idea for the test was simple; two similar cars, one with a standard reservoir and one with the new finned reservoir would compete in the Score, San Felipe 250. The miles of sandy whoops that make up most of the San Felipe race course are known for punishing shocks. The constant, high speed cycling sends shock fluid temperatures through the roof.

King would enlist the help of Wilson Motorsports and their nearly identical Jimco, class one racecars. Randy and Ronny Wilson and their crewchief Mike Stapleton have worked with King Shocks for years helping to test King’s latest ideas. The two cars share the same engines, transmissions, suspensions and shock packages. Everyone involved was hoping to get valid results but nobody expected how equally the cars would perform and how accurate the test data would be. They would each run trouble free all day. They started the race and finished about five minutes apart taking second and third in class one.

According to King Shocks engineer Jeff Larson’s official report: Test data was recorded by the use of two identical temperature data loggers. Each logger had 3 thermocouple channels available and was programmed to record the temperature of all three channels once every minute. The data gathered was graphed vs. time. The profile of each car had similar peaks and valleys. The cars performed similarly all day as the terrain on the race course and the speed of the cars changed creating temperature cycles. Since both cars had the same cycles, it is reasonable to compare peak temperatures between the cars as well as averages. A laboratory test could not have been any better. The fact that the cars both finished the race without problems within similar times makes the value of the collected data priceless.

The temperatures on the shock with the finned reservoir were up to 107 degrees cooler then the same shock with a standard reservoir. That’s a 30% reduction in peak temperature under the most extreme racing conditions. The new finned reservoir from King is durable, has no moving parts and is proven to reduce temperatures. The finned reservoir is currently available for 4.0 and 4.5 diameter shocks with more applications in the works. When you ride on King shocks you’ll know, there really is a difference. Nothing rides like a King.

Photos By: High Rev Photography, Mikes Race Photo.com

According to King Shocks engineer Jeff Larson’s official report: Test data was recorded by the use of two identical temperature data loggers. Each logger had 3 thermocouple channels available and was programmed to record the temperature of all three channels once every minute. The data gathered was graphed vs. time. The profile of each car had similar peaks and valleys. The cars performed similarly all day as the terrain on the race course and the speed of the cars changed creating temperature cycles. Since both cars had the same cycles, it is reasonable to compare peak temperatures between the cars as well as averages. A laboratory test could not have been any better. The fact that the cars both finished the race without problems within similar times makes the value of the collected data priceless.

The temperatures on the shock with the finned reservoir were up to 107 degrees cooler then the same shock with a standard reservoir. That’s a 30% reduction in peak temperature under the most extreme racing conditions. The new finned reservoir from King is durable, has no moving parts and is proven to reduce temperatures. The finned reservoir is currently available for 4.0 and 4.5 diameter shocks with more applications in the works. When you ride on King shocks you’ll know, there really is a difference. Nothing rides like a King.

Photos By: High Rev Photography, Mikes Race Photo.com

You must login to post comments.